BelloCell-500 A

- Productivity: up to 109 cell/bottle

- Facilitate cell seeding, virus infection, transfection, and cell harvest

- Non-pyrogenic, non-cytotoxic

- Pre-sterilized (gamma-irradiated) and ready-to-use

Trade Description

Product Feature

|

High-density Cell Culture System for Research & Development

BelloCell-500A bottle is the alternative of BelloCell-500 designed for improving seeding and inoculation in the process of cell culture. When inverting the bottle after replacing the vented cap with non-vented cap, BioNOC II matrices with the medium are restricted in a narrower space in the non-vented cap, leading to relatively higher matrix (or cell) density for cell seeding, virus inoculation, or trypsinization of cells.

One BelloCell-500A bottle is equivalent to dozens of roller bottles. It is applicable in seeding, binding assay/ human proteome/new drug discovery, virus production, recombinant protein production/ monoclonal antibody production, transient transfection, and tissue engineering.

Check other products of the BelloCell family on the right for your specific application.

|

Specification:

|

BelloCell-500A |

|

|

Function |

For culture of anchorage-dependent cells |

|

Dimension |

100 (ψ) × 243 (h)mm |

|

Working Volume |

500 ml |

|

Material |

PETG, LDPE/EVA, PP |

|

Cap Type |

Vented screw cap |

|

Vent Filter |

0.22 μm PTFE membrane |

|

Additional Cap |

Non-vented screw cap |

|

Carrier Quantity |

865 pc (±5%) BioNOC II, ~5.5 g |

|

Growth Area |

>15,600 cm2 |

|

Sterilization |

Gamma irradiated |

|

Cell Line |

CHO, BHK, VERO, HEK-293, Sf-9, PK, Hi-5, HeLa, ST, 3T3, MDBK, C-127, MDCK, Huh7, RK-12, Hybridoma, Primary cell |

|

Storage |

RT |

|

Shelf Life |

2 years |

Principle:

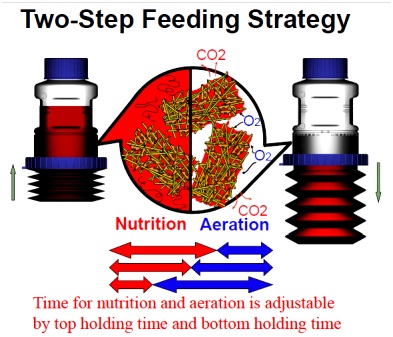

The principle of BelloCell-500A is to immobilize cells onto the BioNOC II matrices packed in its upper chamber. By compressing and decompressing the bellow of BelloCelll-500A by BelloStage machine, the culture medium inside rises and descends, submerging and exposing matrices periodically. During aeration, cells attached to porous matrices are exposed to the air through a thin liquid film. In the submerging phase, cells are in direct contact with the fresh medium for up-taking nutrients while metabolic waste can be diffused as well as CO2 can be exhausted efficiently. The concept of the design is to solve problems (shear stress, limited oxygen supply, and low cell density) frequently occurring on the commercial models, and to simplify the operation.

|

BelloCell-500A

|

|

|

Output

|

Up to 109 cells

|

|

Shear Stress

|

Low

|

|

Foaming

|

No

|

|

Cell Doubling Time

|

Shorter

|

|

Direct Cell Count

|

Yes

|

|

CPE Observation

|

Yes

|

|

Cell Harvest

|

Yes

|

|

Extra Benefit

|

Ø Localize cell and thus increase cell adherence efficiency

Ø Increase cell-to-virus contact for infection or chemical-based transfection

Ø Save enzyme for cell detachment from the matrix

Ø Suitable for slowly adherent cells

Ø Suitable for transit transfection application

|

|

Product

|

Cat. No.

|

Availability

|

|

BelloCell-500A Bottle, 4 bt/cs

|

BCA00500

|

In Stock

|

|

BelloStage-3000 Machine Set

Ø BelloStage-3000 Control Panel x 1 set

Ø Control Box x 1 set

Ø Forceps x 2 pc

Ø CVD kit (50 ml) x 1 bt

Ø Ball Screw Grease (SR-1) x 5 ml/bt

|

BCS03000

|

In Stock

|

|

BelloCell System Complete Set

Ø BelloStage-3000 Machine Set x 1 set

Ø GlucCell Glucose Monitoring System x 1 set

|

BCS04000

|

In Stock

|

|

Forceps , 25 cm, 1pc/pk

|

BCA02000

|

In Stock

|

|

Crystal Violet Dye Nucleus Count Kit, 100 ml/bt

|

BCA02001

|

In Stock

|

|

BelloCell Filtered Cap, 6 pc/cs

|

BCA02003

|

In Stock

|

|

Non-vented Cap, 8 pc/pk

|

BCA02004

|

In Stock

|

|

BelloCell-500A Strainer, 1 pc/pk

|

BCA01206

|

In Stock

|