TideXCell-002 Pro HD Cell Culture System

TideXCell-002 Pro HD Cell Culture System is a bench-top, fixed-bed bioreactor utilizing an unique respiratory culture principle under low shear stress and high aeration capability. The system can culture cell from 6 x1010 in a small operation footprint, which is equivalent to conventional 75 L stir tank bioreactor.

Trade Description

Product Feature

Principle:

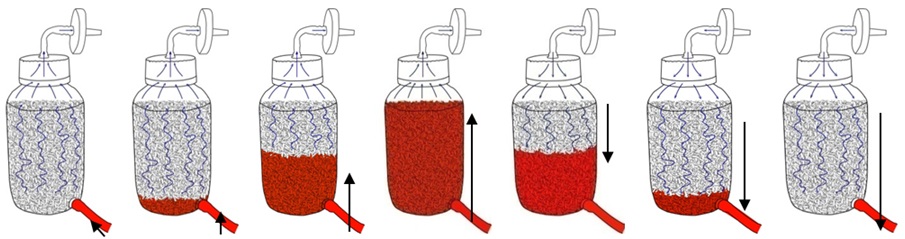

TideXCell HD Cell Culture System inherits the same patented principle of BelloCell systems. Packed with porous BioNOC II matrices, the matrix vessel functions as an artificial lung with a huge contact surface for nutrition and aeration for cell culture. The culture medium is periodically drawn from the external Mixing Bag into the matrix vessel to submerge the matrices and withdrawn from the vessel to expose the matrices, driven by the applied air pressure. Thus, cells entrapped inside the matrices are able to receive sufficient nutrients and oxygen, while metabolic wastes such as lactate and carbon dioxide can be efficiently carried away in a gentle manner. The concept of the design is to solve problems (shear stress, limited oxygen supply, and low cell density) frequently occurring on the commercial models, and to simplify the operation.

|

The culture medium in the external mixing bag, homogenized by different agitation methods, flows between the matrix vessel in the incubator and mixing bag by the switch-over of negative / positive air pressures, submerging the matrices where cells attach. As a result, the matrices are submerged and exposed to air periodically. During the submerging phase, fresh nutrients replenish, and metabolic wastes are diffused and then carried away. Meanwhile, the carbon dioxide is forced to exhaust. During aeration, clean air is introduced and contacts with the porous matrices through a thin liquid film. The oxygen transfer efficiency is maximized. The culture medium is re-mixed and tuning for pH/DO in the mixing bag. |

Resource:

2. Reference

3. Q&A

|

Hardware

|

TideXCell-002 High-Density

Cell Culture System

|

| Production scale |

2 L Matrix Vessel (110 g BioNOC II carriers), and 10~100 L Mixing vessel with culture media depending on process requirement

|

| Equivalent roller bottle (850 cm2) |

400

|

| Equivalent conventional batch system |

75 L

|

| Shear stress |

Low

|

| Foaming |

No

|

| Productivity |

Up to 6 X 1010 cells

|

Product Description

|

Base Unit |

|

|

Weight |

240 kg |

|

Required space (W x H x D) |

1250 x 1150 x 700mm |

|

Power supply |

220 VAC 50/60Hz |

|

Housing |

Outter 304 stainless steel |

|

Working volume |

1 ~ 5L, Using disposable or reusable matrix vessel 1L, 2 L matrix vessel (glass), 5L (PP) |

|

Max. surface area for cell growth |

31.2 m2 |

|

Operating temperature |

18 ~ 27 °C |

|

Maximum relative humidity |

80% for temperatures up to 31 °C decreasing linearly to 50% relative humidity at 40 °C, non-condensing environment, non-condensing environment |

|

TideMotion flow rate |

800 ~ 1800 ml/min |

|

Interfaces |

- Ethernet for SCADA system - USB - Aux USB - Interface to TideXCell®-002 Pro Mixer PT-100 thermometric sensor - Interface to TideXCell®-002 Pro Mixer load cell - Interface to TideXCell®-002 Pro Mixer power - Interface to TideXCell®-002 Pro Mixer agitation signal - Interface to TideXCell®-002 Pro Mixer electric heating jacket - Interface to TideXCell®-002 Pro Mixer pH probe - Interface to TideXCell®-002 Pro Mixer DO probe - Alarm Relay |

|

Ports |

- Air In for air source - N2 In for N2 source - O2 In for O2 source - CO2 In for CO2 source - F.Cir-Out for force circulation function - Mix-Gas for gas supplement to TideXCell®-002 Pro Mixer |

|

Peristaltic Pump Module |

|

|

Quantity |

4 |

|

Controller |

Fixed speed (regulated on|off) |

|

Speed |

100 rpm |

|

Pump head |

Watson Marlow 114, Fast Load pump head |

|

Flow rates |

MasterFlex L/S 25 Silicone tubing ID 3/16”: 75 ml/min MasterFlex L/S 16 Silicone tubing ID 1/8”: 45 ml/min |

|

Process Control and Measurements |

|

|

Temperature |

- Temperature control with Heating coil - Temperature control for RT+8 ~ 45.0 °C - Display resolution 0.1°C - Heating power: 780 W |

|

O2 Concentration |

- O2 Concentration control with Air and N2 gas injection - O2 Concentration control for 5%~20% - Display resolution 0.1°C |

|

CO2 Concentration |

- CO2 Concentration control with CO2 gas injection - CO2 Concentration control for 0%~10% - Display resolution 0.1°C |

|

Aeration Module |

|

|

Gas inlet |

- Gas pressure: 1.2 ~ 1.5 barg - Gases: dry, oil and dust-free - Gas inlet connections with quick couplers for 4 x 6 mm reinforced tubing |

|

Gas outlet |

- Gas pressure: max .1 barg - Gas outlet connections with quick couplers for 4 x 6 mm reinforced tubing |

|

Aeration control |

- Continuous and automatic aeration control for air, O2, N2 and CO2 - Gas flow control units with mass flow meter: Total of four; one per gas source - Flow rates of the gas flow control units: Air, N2, and CO2: 0 ~ 10 L/min O2: 0 ~ 5 L/min |

|

Interface |

|

|

Control |

Siemens PLC |

|

Display |

Siemens HMI |

|

Optional external unit |

Adaptable to TideCell SCADA System and Cell Harvest System |

|

Regulatory compliance |

CE |

BelloStage (3000/7000)

BelloStage (3000/7000) BioNOC II Matrix

BioNOC II Matrix Single-Use Bioprocess Bags

Single-Use Bioprocess Bags TideCell Cell Harvest System

TideCell Cell Harvest System TideCell Matrix Vessel

TideCell Matrix Vessel TideCell Thermostatic Mixing System

TideCell Thermostatic Mixing System TideCell-010 HD Cell Culture System

TideCell-010 HD Cell Culture System TideCell-020 HD Cell Culture System

TideCell-020 HD Cell Culture System TideCell-100 HD Cell Culture System

TideCell-100 HD Cell Culture System